With the continuous development of the manufacturing industry, high-speed press technology plays an increasingly important role in the field of metal processing, HOWFIT has been committed to the research and innovation of high-speed press technology, and constantly promote the development of this field. In this paper, we will discuss the development trend of HOWFIT high-speed press technology from the basic concept and application field of high-speed press, technological innovation as well as digitalization and automation application in three aspects.

1. The basic concept and application field of high-speed punch press

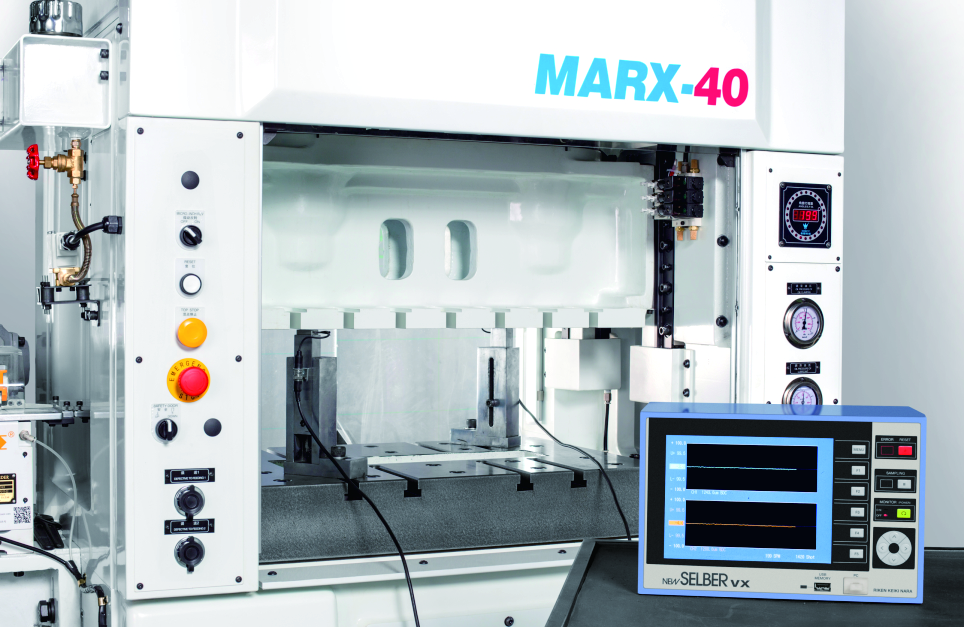

High-speed punch press is a kind of machine tool used for impact processing of metal materials, and its working principle is to carry out high-speed impact on metal materials through the punch, so as to realize the cutting, punching and molding of metal plates and other processing. High-speed punch press has the characteristics of fast processing speed, high precision and superior efficiency, so it is widely used in the fields of automobile parts, electronic equipment, home appliance manufacturing and so on.

2. Technological innovation: the latest innovation and development trend of high-speed punch press technology

In terms of technological innovation, HOWFIT keeps pushing forward and devotes itself to improving the performance and functions of high-speed presses. The latest innovations mainly focus on the following aspects:

2.1 High-speed drive technology

HOWFIT introduces advanced high-speed drive technology, which realizes precise motion control of high-speed punch press through motor control system, improves the processing speed and response speed of the punch press, and at the same time reduces energy consumption, making the whole production process more efficient.

2.2 Intelligent control system

Intelligent control system is another breakthrough in high-speed press technology, and HOWFIT introduces artificial intelligence, machine learning and other advanced technologies to make the press have stronger self-adaptive ability and intelligence, which can automatically adjust the process parameters according to the characteristics of different workpieces, and improve the flexibility and adaptability of production.

2.3 Application of lightweight materials

HOWFIT high-speed punching machine adopts lightweight materials in its design, such as high-strength aluminum alloy and composite materials, in order to reduce the weight of the machine tool itself, improve the machining speed and positioning accuracy of the machine tool, and at the same time, reduce vibration and noise, and enhance the stability of the whole machine.

3. Digitalization and automation: the key to improving productivity

Digitalization and automation is the current trend of the manufacturing industry, and in the field of high-speed presses also has an important application.

3.1 Digital production management

HOWFIT high-speed punch press realizes comprehensive monitoring and management of the production process through digital production management system. This system can collect production data in real time, analyze and forecast, help enterprises optimize production plan and improve production efficiency.

3.2 Automated loading and unloading system

The introduction of automated loading and unloading system enables high-speed presses to realize a higher degree of automation, and HOWFIT realizes the automatic loading and unloading of workpieces through robots and automation devices, which reduces manual intervention and improves the stability and efficiency of the production line.

In summary, HOWFIT high-speed punch press technology in the continuous innovation and development, through the introduction of advanced technology and digital means, to achieve the high-speed punch press in the production efficiency, precision and stability of the overall improvement. With the continuous development of the manufacturing industry, we can look forward to the high-speed press technology in the future application areas to show a broader space for development.

For more information, please visit HOWFIT official website

For more details or purchasing inquiries, please contact:

howfitvincentpeng@163.com

sales@howfit-press.com

+86 138 2911 9086

Post time: Dec-28-2023