Introduction:

The headstock machining process plays a crucial role in modern mechanical engineering. This article will delve into the unique aspects of the headstock machining process in the HOWFIT DDH 400T ZW-3700 high-speed precision punch press and how this process safeguards manufacturing quality.

Annealing and Treatment:

The first step in ensuring the manufacturing quality of the DDH 400T ZW-3700 is that the castings are twice annealed and vibration aged. The two anneals effectively reduce internal stresses, while the artificial interference of the vibratory aging treatment further removes internal stresses to 98%. This series of treatment ensures the stability of the machine’s manufacturing quality and lays a solid foundation for the subsequent processes.

Finishing:

The annealed and treated headstock undergoes finishing, a step that is critical to the high precision and quality of the product. The adoption of a pre-stressed eight-sided circular needle roller guided slide ensures the balance of lateral force when the slide base is eccentrically stamped, which in turn ensures the perpendicularity and parallelism of the slide’s up and down movement. The superiority of this design makes the mold production cycle longer and more durable.

Testing:

To ensure the high quality of the machine before delivery to customers, DDH 400T ZW-3700 is inspected with a laser tracker (API, USA). This high-precision inspection means can comprehensively and accurately assess the parameters of the machine, thus guaranteeing the reliability of the manufacturing quality.

Performance parameter profiling:

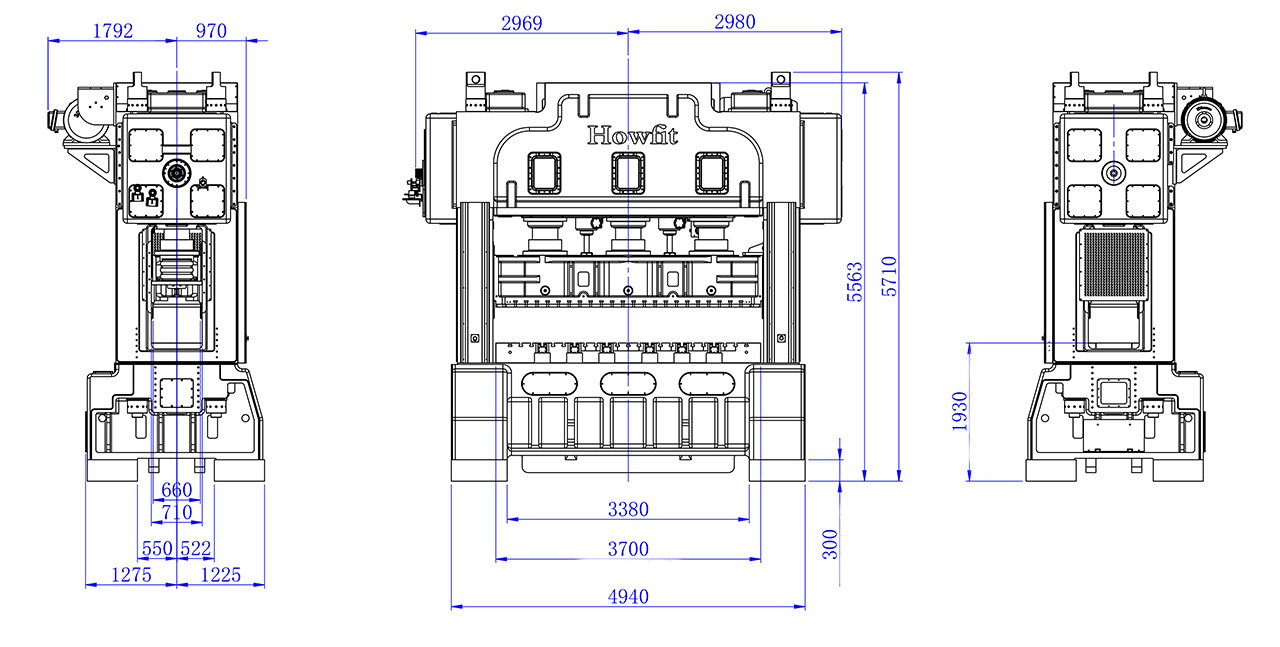

The DDH 400T ZW-3700 stands out in the industry with its high performance. From the nominal force, to the motor power, to the table area, each parameter highlights the excellence of this press in different working conditions.

- Nominal force: The nominal force of 4000KN enables the DDH 400T ZW-3700 to excel in a wide range of processes, guaranteeing the realization of efficient stamping.

- Motor Power: The 90kw motor power not only provides strong power support for the machine, but also guarantees the reliability of the machine in high speed operation.

- Table area: The table area of 3700x1200mm makes the DDH 400T ZW-3700 suitable for processing large-sized workpieces to meet diversified production needs.

By analyzing these performance parameters, we have a deeper understanding of the superior performance of the DDH 400T ZW-3700 in different application scenarios.

Conclusion:

HOWFIT DDH 400T ZW-3700 has made a name for itself in the field of mechanical engineering with its unique headstock machining process and superior performance. Through the introduction of advanced manufacturing processes and precise inspection methods, this high-speed precision punch press provides customers with high-quality and high-efficiency machining solutions.

For more information, please visit HOWFIT official website

For more details or purchasing inquiries, please contact:

howfitvincentpeng@163.com

sales@howfit-press.com

+86 138 2911 9086

Post time: Dec-22-2023