The widespread adoption of new energy vehicles (NEVs) in recent years has created a growing demand for efficient and reliable manufacturing processes. One of the key components of new energy vehicles is the battery. In order to ensure the safety of the battery, an explosion-proof disk is used. Stamping plays a vital role in the production of these panels, providing efficiency, precision and durability. Sheet metal stamping machines have become the first choice for this critical task.

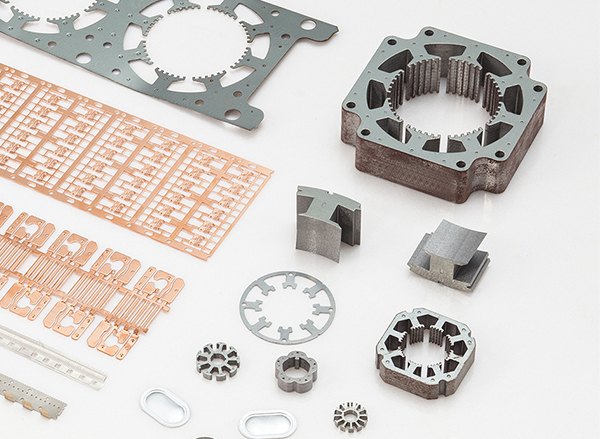

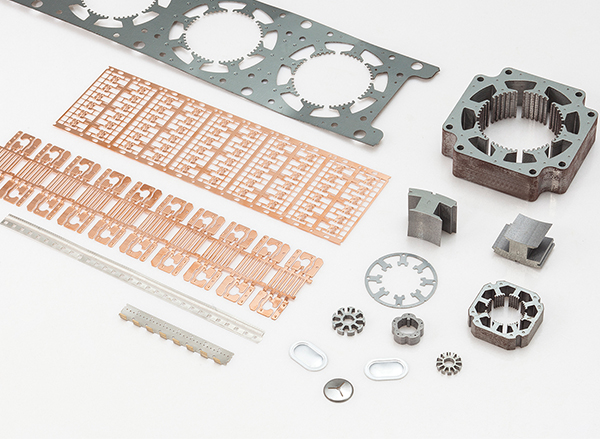

Presses are heavy equipment used to form and shape sheet metal. They use powerful hydraulic or mechanical mechanisms to apply pressure to metal to create intricate shapes and designs.stamping machines have proven their value in the manufacture of explosion-proof panels for new energy vehicle batteries.

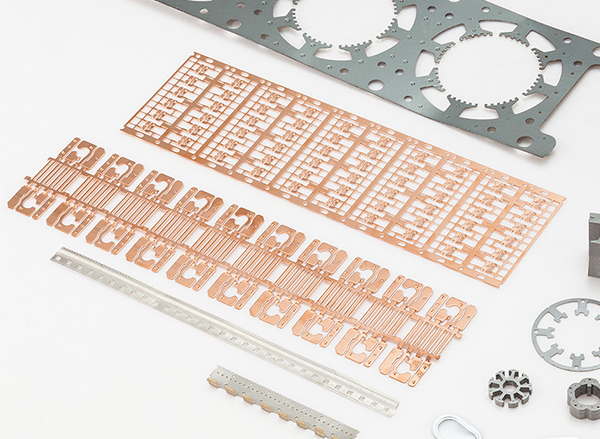

Known for its strength and durability, steel was the ideal material for this particular application. These presses are equipped with steel-specific features such as high tonnage capacity and mold heating to ensure precise and efficient machining. Bursting discs require complex designs to fit specific battery models, which is easily accomplished with the versatility of stamping machines.

The high tonnage capabilities of high speed precision press enable deep drawing, a forming process that uses flat metal to form three-dimensional shapes. In the production of explosion vents, deep drawing can create complex custom designs with minimal material waste. Furthermore, the exceptional strength of the steel ensures that the resulting panels can withstand high levels of impact, providing the required blast protection.

In addition, stamping machines usually have a mold heating function. This feature allows rapid heating of the sheet metal before the stamping process begins, helping to form complex designs. In addition, the heated mold also reduces the risk of surface defects in the rupture disc, further improving the safety and reliability of new energy vehicle batteries.

The application of high speed precision press in the stamping process of explosion-proof panels for new energy vehicle batteries has brought many benefits to manufacturers. First of all, the stamping machine has high efficiency and can achieve mass production to meet the growing demand for new energy vehicle batteries. The precise and consistent results obtained minimize the need for manual adjustments, reducing production time and costs.

In addition, the durability and strength of stamped explosion-proof discs ensure the long-lasting reliability of new energy vehicle batteries. Steel can provide the necessary protection against a potential battery explosion, keeping the vehicle and its occupants safe. In addition, the versatility of the stamping machine can produce a variety of explosion-proof panels for new energy vehicles to meet the diverse needs of the market.

With the growing demand for new energy vehicles, the importance of efficient and reliable manufacturing processes cannot be overemphasized. The stamping machine has been proven to be the best solution for the stamping process of the new energy vehicle battery explosion-proof plate. Their strength, precision and versatility help produce high-quality panels while also ensuring the safety and reliability of new energy vehicle batteries.

Post time: Jul-17-2023