Knuckle Type Precision Press Precision Stamping Machine 40T

Product Description

Another noteworthy feature of this press is its high impact and wear resistance. The guide materials used in its construction have been specifically selected to withstand heavy use and provide long-term stability. This means you can expect your press’s accuracy to remain consistent over a longer period of time, reducing the need for frequent repairs and maintenance. With this advanced durability, you can focus on maximizing production rather than worrying about wear and tear on your machine.

In addition to excellent performance, the Knuckle High Speed Precision Press features a stylish and ergonomic design. The intuitive control panel allows for easy operation and adjustment, ensuring a seamless user experience. The press is also equipped with advanced safety features, including an emergency stop button and a protective cover to ensure operator health and prevent accidents.

Main Technical Parameters:

| Model | MARX-40T | ||||

| Capacity | KN | 400 | |||

| Stroke length | MM | 16 | 20 | 25 | 30 |

| Maximum SPM | SPM | 1000 | 900 | 850 | 800 |

| Minimum SPM | SPM | 180 | 180 | 180 | 180 |

| Die height | MM | 190-240 | |||

| Die height adjustment | MM | 50 | |||

| Slider area | MM | 750x340 | |||

| Bolster area | MM | 750x500 | |||

| Bed opening | MM | 560x120 | |||

| Bolster opening | MM | 500x100 | |||

| Main motor | KW | 15x4P | |||

| Accuracy | JIS/JIS Special grade | ||||

| Upper Die Weight | KG | MAX 105/105 | |||

| Total Weight | TON | 8 | |||

Main Features:

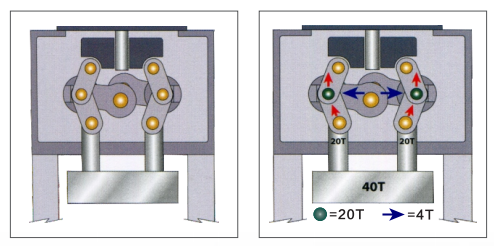

1.The knuckle type press maximizes its mechanism characteristics.it has the characteristics high rigidity.high accuracy and good heat balance.

2.Equipped with compelte counterbalance,reduce the displacement of die height due to the stamping speed change,and reduce the bottom dead point displacement of the first stamping and the second stamping.

3.Adopted balance mechanism to balance each side1 s force,its structure is eight-sided needle bearing guiding,further improve the eccentric load capacity of the slider.

4.New non-backlash clutch brake with long life and low noise,achiece more quiet press work.The size of the bolster is 1100mm(60 tonnage) and 1500mm(80 tonnage),which is the widest for their tonnage in ourfull range of products.

5.With servo die height adjustment function,and with die height memory function,reduce the mold change time and improve production efficiency.

Perfect Stamping Effect:

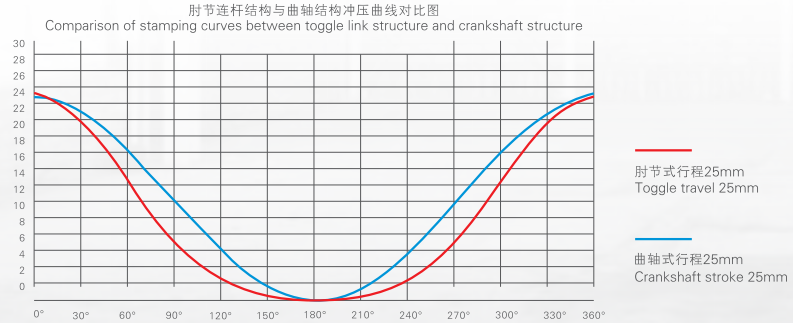

Horizontally symmetrical symmetrical toggle linkage design ensure the slider moving smoothly near the bottom dead center and achieve a perfect stamping result,which meets the stamping requirements of lead frame and other products.Meanwhile,the motion mode of the slider reduces the impact on the mould at the time of high-speed stamping and prolongs the mould service life.

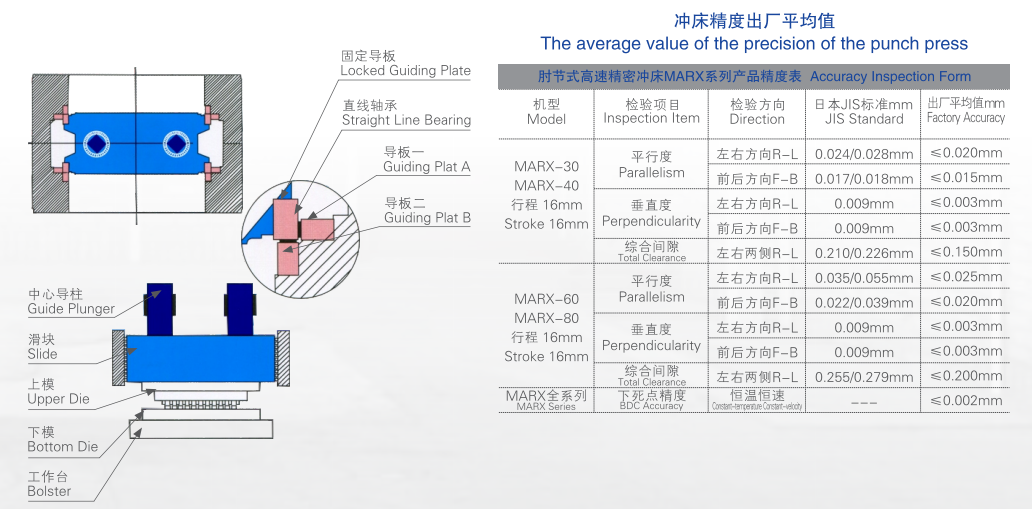

MRAX Superfine Precision一一Good Rigidity and High Precision:

The slider is guided by a guide of double plungers and octahedral flat roller with nearly no clearance in it.lt has good rigidity,high inclined loading resistance capability,and high punch press precision.High impact-resisting and wear-resisting property of the

Knuckle Type High Speed Precision Press

guide materils guarantee long-term stability of the press machine precision and prolong the intervals of repairing mould.

Structure Diagram

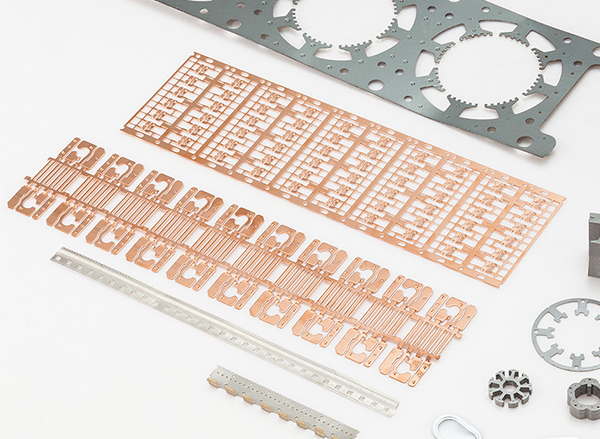

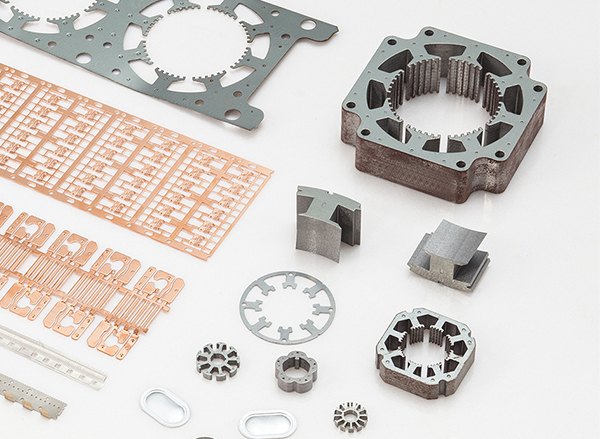

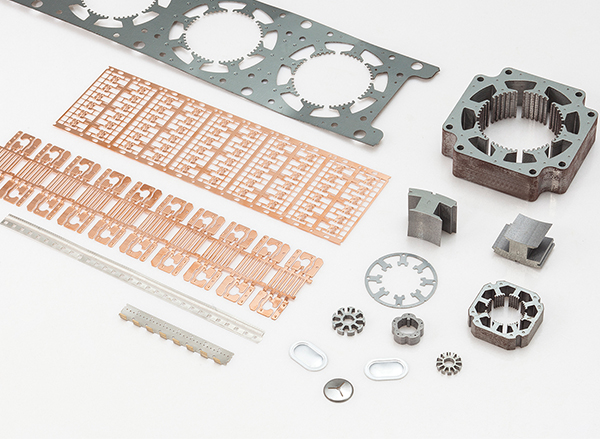

Press Products

Lead Frame

The die inside the package is typically glued to the lead frame, and then bond wires attach the die pads to the leads. In the last stage of the manufacturing process, the lead frame is moulded in a plastic case, and outside of the lead frame is cut-off, separating all leads.

Lead frames are manufactured by removing material from a flat plate of copper or copper-alloy. Two processes used for this are etching (suitable for high density of leads), or stamping (suitable for low density of leads). Stamping(punching or pressing) is the most effective, precise and high-tech way to produce Lead Frame nowadays.

The basic reason for the injury to agriculture caused by 60 Tons Knuckle Type High Speed Stamping Press is the lack of necessary protective devices and facilities, and the lack of effective labor protection for dangerous working procedures. The technical cause of the injury accident of punch press is the imbalance between the operator's action and the operation of the machine tool.