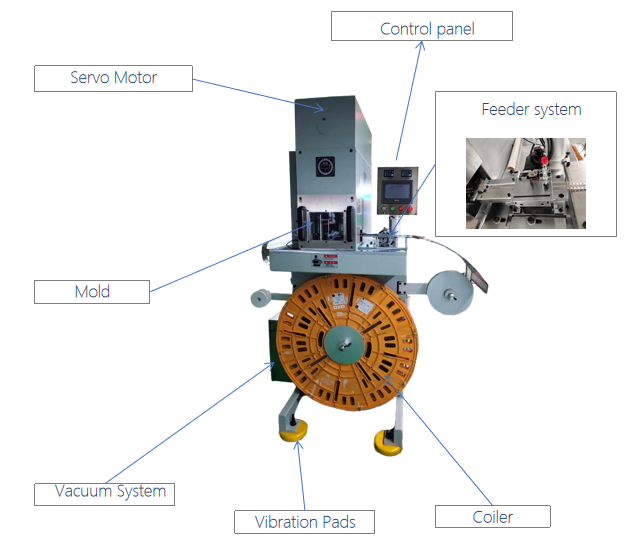

High Speed Precision Mini Type Servo Press

Mini Type Servo Press Information

| HSF-5T Key Specification | ||

| Description | Unit | Spec |

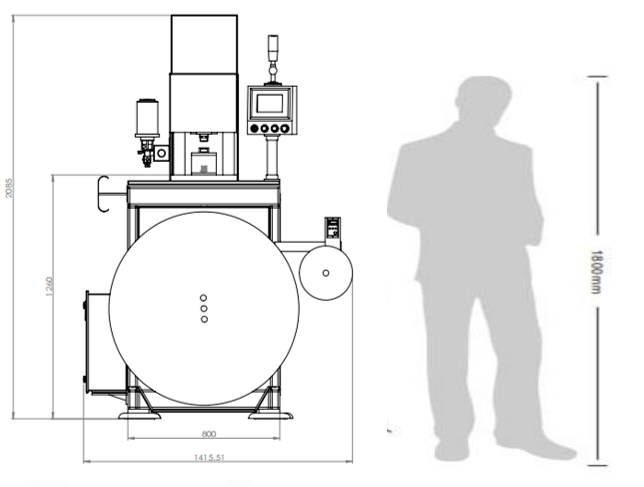

| Press capacity | KN | 50 |

| Stroke length | mm | 20 |

| Stroke per minute | SPM | 5~500 |

| Die height | mm | Customizable |

| Bolster | mm | 220×300 |

| Slider lower area | mm | Customizable |

| Bed opening | mm | Customizable |

| JIS Accuracy | - | Super grade |

| Max.weight of upper die | kg | 20 |

| Servo capacity | KW | 3 |

| Machine weight | kg | 900 |

| Feeder Key Parameter | ||

| Feeder | - | Servo roller |

| Feeding width | mm | 5-40 |

| Material thickness | mm | MAX 0.8 |

| Feed servo | KW | 0.75 |

| Feed direction | - | Left → Right |

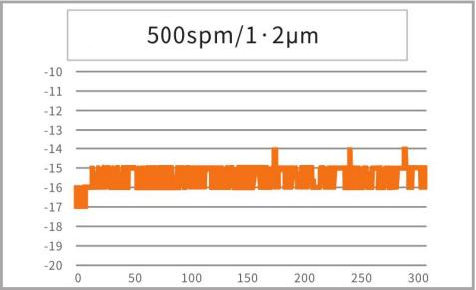

✔ Bottom dead point accuracy

✔ The deviation of each mold is: 1 ~2μm(500spm)

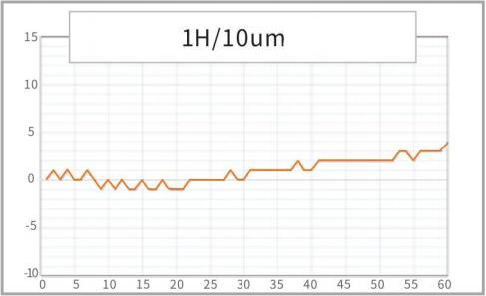

✔ Bottom dead point accuracy

✔ Heat deviation: 10μm/1H( 500s pm )

Advantage of HSF-5T

1. The accuracy of the bottom dead center is high, the accuracy can reach 1-2um (0.002mm), and the stable performance is high during production.

2. It is not limited by the origin of the floor, and can be used on the second floor or above.

3. Wide range of application scenarios, can be connected with the production line to achieve full automation.

4. Save mold manufacturing and maintenance costs.

5. Specifications can be customized according to customer needs.

6. Especially suitable for some oil-free stamping products, can replace the market pull up and down press.

Application Case

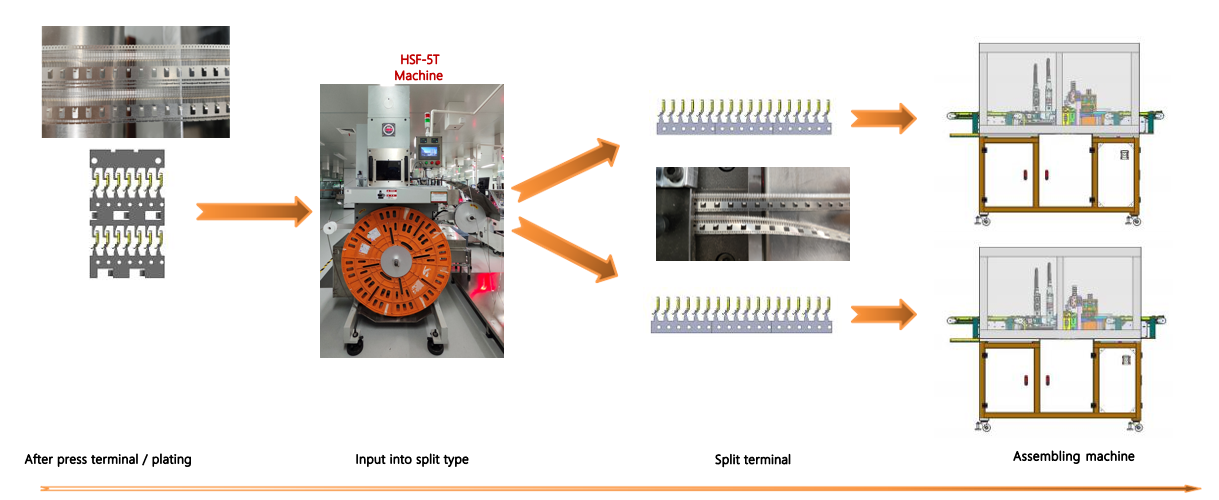

● Split the two row terminal and put it into the assembly production line.

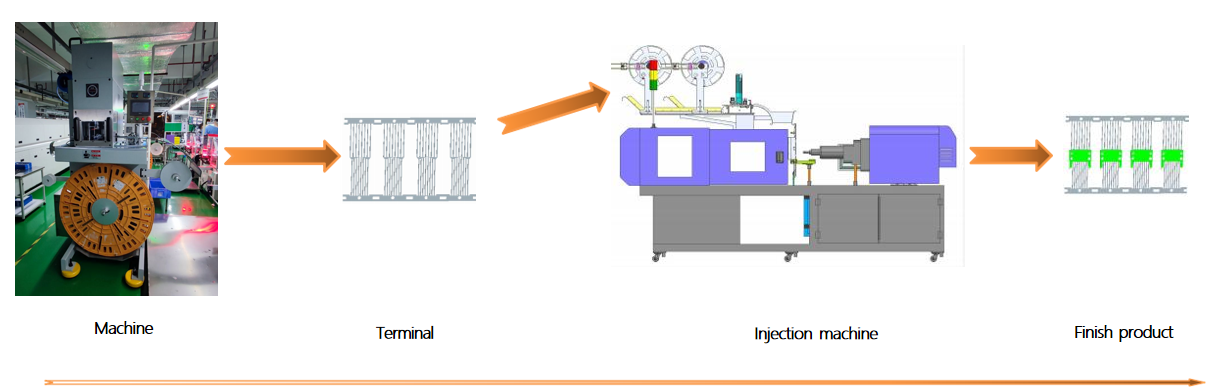

● Stamping and injection molding integration.

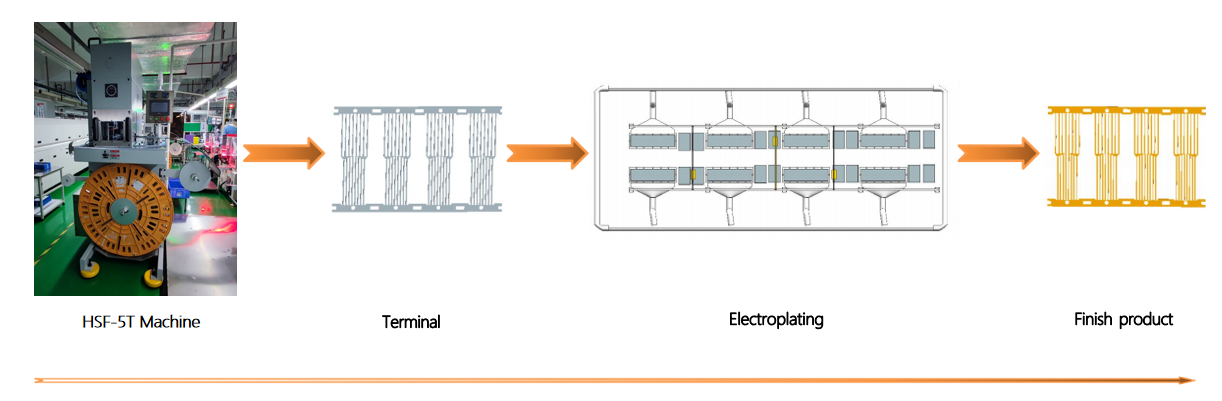

● Stamping electroplating integration.

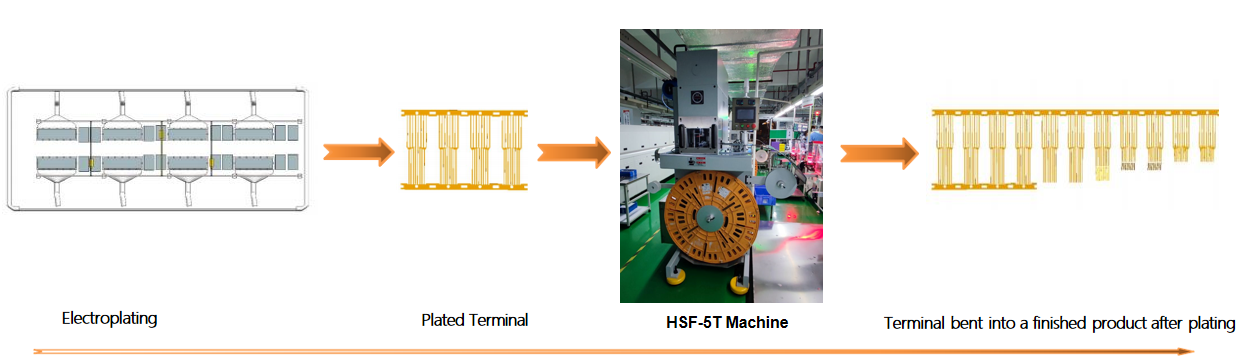

● Stamping and bending integration before and after electroplating

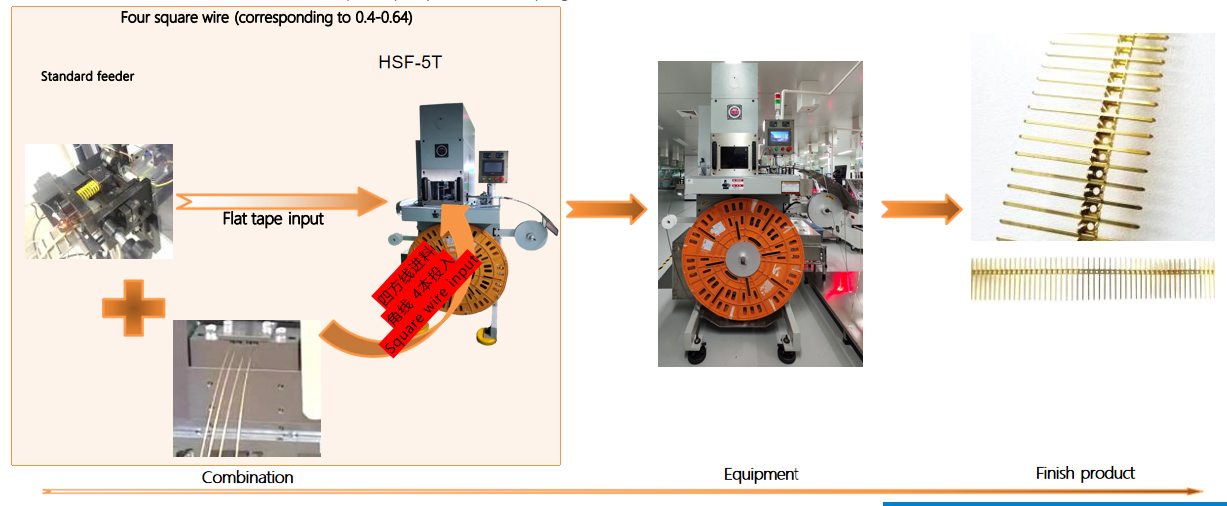

● Square pin product stamping combination

Product Configuration