DDH-125T HOWFIT High Speed Precision Press

Main Technical Parameters:

|

Model |

DDH-125T |

|

|

Capacity |

KN |

1250 |

|

Stroke length |

MM |

30 |

|

Maximum SPM |

SPM |

700 |

|

Minimum SPM |

SPM |

150 |

|

Die height |

MM |

360-410 |

|

Die height adjustment |

MM |

50 |

|

Slider area |

MM |

1400x600 |

|

Bolster area |

MM |

1400x850 |

|

Bed opening |

MM |

1100x300 |

|

Bolster opening |

MM |

1100x200 |

|

Main motor |

KW |

37x4P |

|

Accuracy |

|

Super JIS /JIS Special grade |

|

Total Weight |

TON |

27 |

Main Features:

♦ The frame is made of high strength cast iron, which eliminates the internal stress of the workpiece through natural long time after precise temperature control and tempering, so that the performance of the workpiece of the frame reaches the best state.

♦ The connection of the bed frame is fastened by the Tie Rod and the hydraulic power is used to prepress the frame structure and greatly improve the rigidity of the frame.

♦ Powerful and sensitive separation clutch and brake ensure precise positioning and sensitive braking.

♦ Excellent dynamic balance design, minimize vibration and noise, and ensure the life of the die.

♦ Crankshaft adopts NiCrMO alloy steel, after heat treatment, grinding and other precision machining.

♦ The non-clearance axial bearing is used between the slide guide cylinder and the guide rod and match with the the extended guide cylinder, so that the dynamic and static accuracy exceeds the special grande precision, and the life of the stamping die is greatly improved.

♦ Adopt the forced lubrication cooling system, reduce the heat strain of the frame, ensure the stamping quality, prolong the press life.

♦ The man-machine interface is controlled by microcomputer to realize visual management of operation, product quantity and machine tool status at a clear sight (central data processing system will be adopted in the future, and one screen will know the working status, quality, quantity and other data of all machine tools).

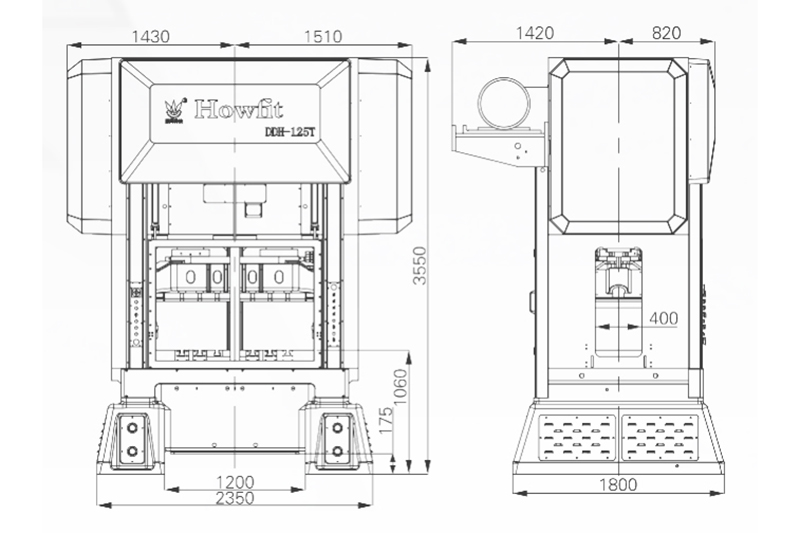

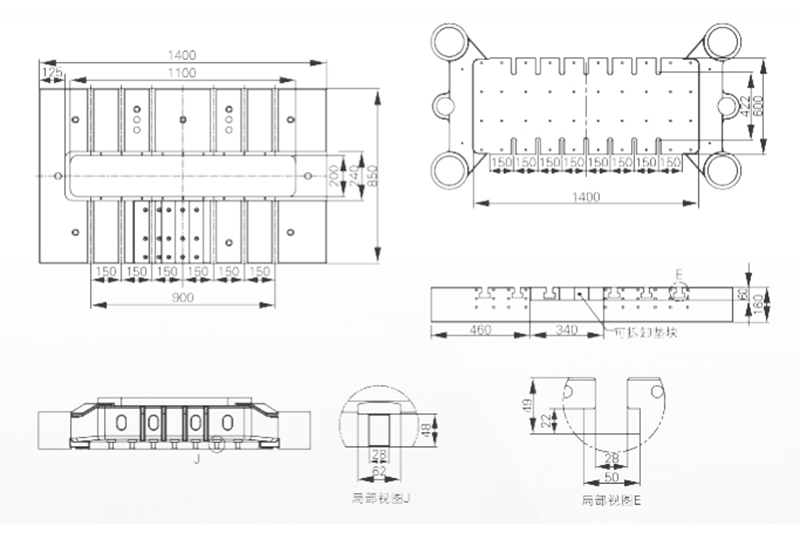

Dimension:

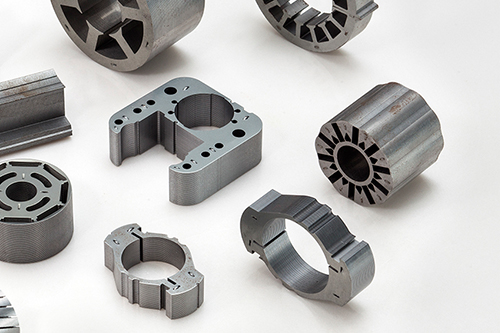

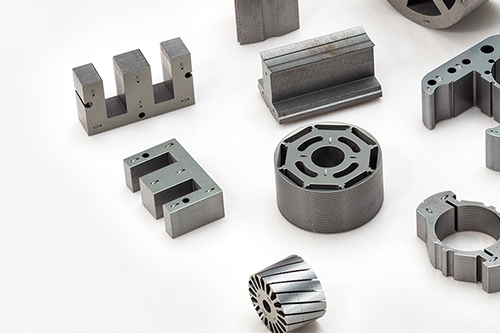

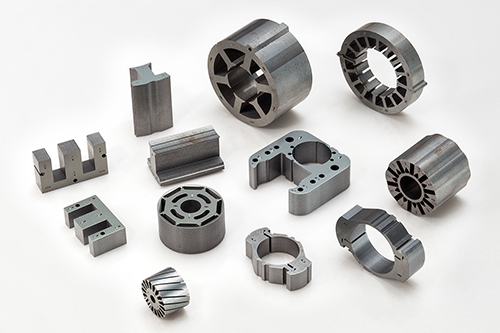

Press Products: